Robotic ImagingSeptember 26, 2022

Designing and building industrial plants is one of the most hectic jobs for professionals because it requires high accuracy and absolute zero errors. With the traditional method, achieving that level of accuracy is nearly impossible. However, using laser scanning services of Robotic Imaging can not only enhance the accuracy and coordination between the manufacturers and the investors but also shortens project schedules.

LiDAR Scan – Standard Practice to Design Industrial Plants

Over time companies and manufacturers have seen the benefits of using LiDAR scan and how it proved cost-effective for specific projects. So now, it has become a standard practice to merge laser scanning services with modeling tools to make projects highly valuable. Robotic Imaging has the experience and laser scanning tools for sizes of projects.

Suggested reading: If you want to learn more about Robotic Imaging's hand in scanning Yonkers' Power Plant, check out this article.

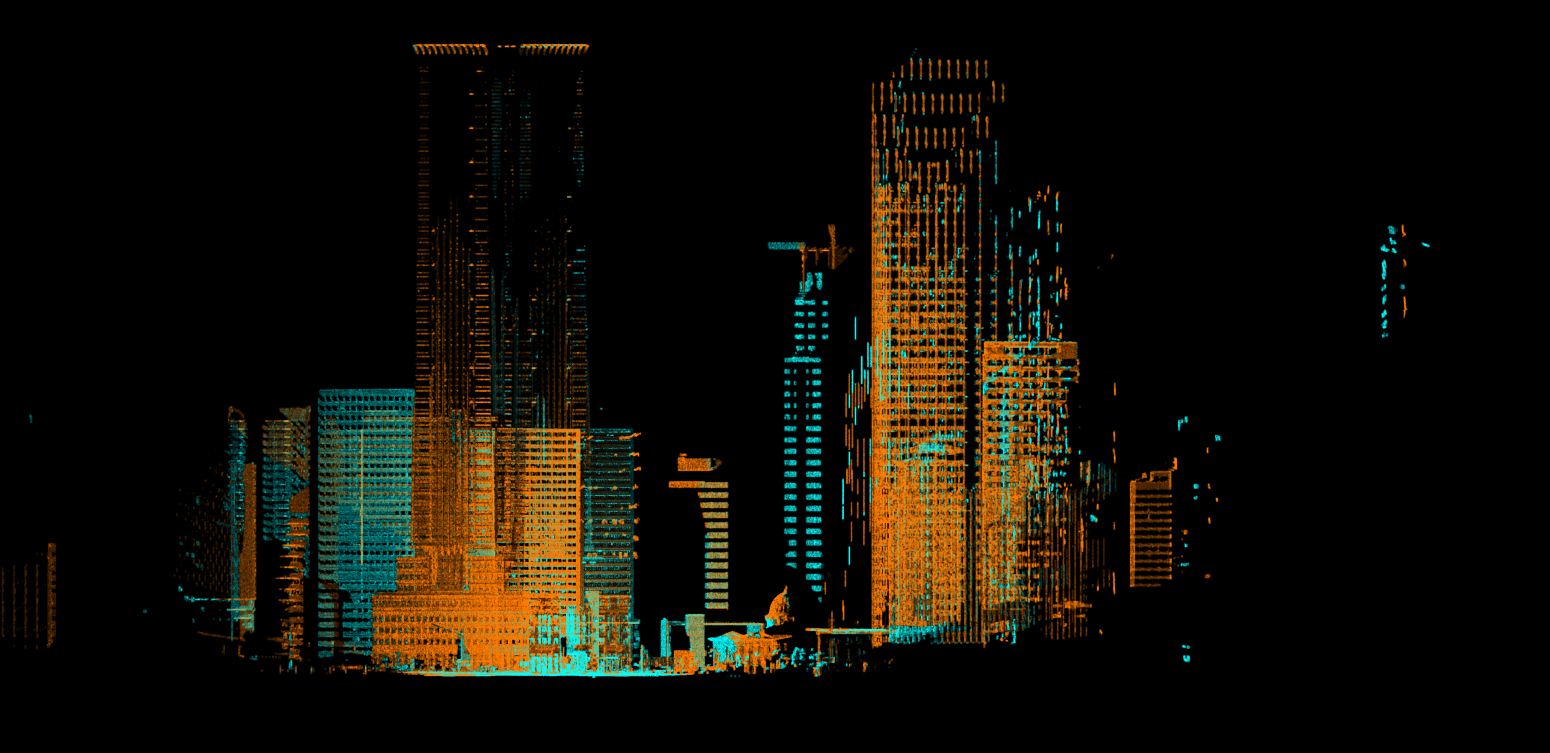

LiDAR is a ranging scanning method that emits infrared light rays. It measures how long it takes to come back to the scanner after hitting nearby objects. This measurement reflects a distance from each object precisely, based on the speed of light. 3D LiDAR laser scanning has multiple applications in the world of real estate and architecture. Commercial real estate developers find Robotic Imaging’s services invaluable, as it saves precious time and money. LiDAR scanning in real estate ensures highly accurate and precise measurements that simply cannot be achieved by hand.

How Can Point Cloud Help with Industrial Projects?

First, when a manufacturing facility hires a super professional company like Robotic Imaging, their job is to utilize their laser scanning solutions for 3D reality and data capturing of all the facility's content.

And then, they hand over their point cloud model to the manufacturers so that they can use it as a backdrop for workplace efficiency, industrial plant placement, or bring it into a solution. Such models are also helpful for 3D accurate calculations of space constraints and clashes / interferences.

Practical Advantages of Laser Scanning in Industrial/ Manufacturing Facilities

In addition to improved costs and efficiency, there are several other advantages of laser scanning in industrial plant design and building processes. Let’s have a look at some of them.

Reduction of Rework

Creating highly accurate industrial plant placement and installation drawings can help align the complete plan. Using Robotic Imaging laser scan services, you can get accuracies of 3mm at a 50m distance. And to create such models, point cloud data is used, and it becomes possible to create several sections and elevations.

Enabling Dynamic Bid Packs

In all honesty, you cannot rely on engineers or your workforce to utilize a measuring tape for capturing industrial/ product plant layouts. And it also requires a large workforce which is costly. Moreover, we all know that bid packs usually lack details and are bloated, making it difficult for the contractors to see unforeseen challenges.

So, the only efficient and cost-effective way to procure realistic bids is by using a PDF bid pack with hyperlinks to point cloud data. Also, that way, a client can supply highly-accurate 3D laser scanned data of the facility areas to the service providers.

The Return on investment of Laser Scanning

Different industries have different plant assembly and design requirements, but usually, it requires millions of dollars, so using technologies and laser scan services offered by Robotic Imaging can be great for saving costs and improving efficiency. Moreover, the company's laser scanning solutions are as dynamic as the manufacturing and industrial facilities' dynamic plant requirements.